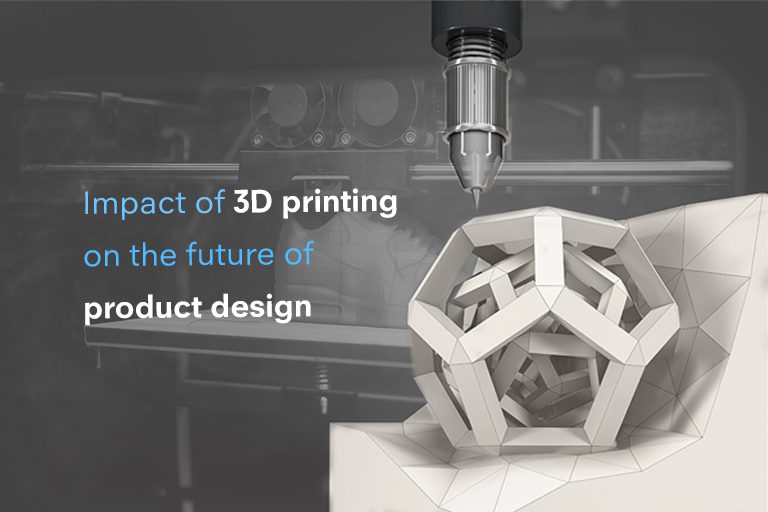

Additive manufacturing or 3-dimensional (3D) printing is having a revolutionary impact on product design. The technology is making changes not only in the production side, but also in how they are designed. With the rapid emerging tech innovation, 3D printing is becoming more affordable and is bound to become a household thing in the future with the availability of materials growing. From airlines, medical industry, industrial manufacturing, automobiles, prototyping and end-use parts – 3D printing is used more often than we realize in products around us.

As the efficiencies grow of additive manufacturing techniques, the transformative effect of the same is bound to happen on product design. One prime reason for this transformation is not only how they are manufactured – but where they are manufactured. Example, this growing technology is offering many countries a return to manufacturing, like the USA.

Also Read: Influence of culture on design

3D printing is transforming ideas into actual concepts faster than any pre-existing manufacturing processes. This allows designers to bring their ideas to life – into their hands – from a computer screen in a matter of a few minutes/hours.

The application of 3D printing in Product Design

While there may be several applications, here are a few that are most common in product design world, also reflect on how this revolutionary technology has impacted the world of product design:

Physical Concepting

In the early stages of design and design development, designers gain a lot by having a physical model of the product and testing the same under various situations to comprehend if the direction of design they are working on is going to work. Designers can now visualize different design changes and iterations quickly – at a lower cost.

With physical concepting the otherwise long process of building a prototype, comparing, testing, making structural changes and building all over again is now much simpler. Product developers can easily compare, test and understand the qualities of their designs both – visually and structurally. It allows them to check proportions, balance ( if the product needs), resilience and if all parts that are designed and manufactured work collectively as a single product.

Also Read: A brand identity designer’s guide to responsive logo design

Rapid Prototyping

Once physical conceptualization of different ideas is completed, the next step is designing a prototype. With 3D printing product designers can build functional prototypes faster than any other process. Fashion to fast moving automobiles, this technology is a game-changer for prototyping.

The process of sending designs to the manufacturer for discussion on building a prototype will be a thing of the past. An in-house 3D printer helps to speed this process up and makes rapid prototyping a real possibility. In 3D printing, product designers can make changes and adjustments on the spot without having to wait for a long period of time.

End-use Production

Tech advancements and industrial grade material have made 3D printing viable for end-use production. Product designers can design and produce small batches of products which are fully functional – and ready for consumption.

Beyond products for consumers, designers can design and build tools, support elements/ pieces that aid in the overall manufacturing process. A product may finally be pieced together by another machine or by human hands, however 3D printing allows to manufacture all its different parts.

Read More: Evolution of creative sketching

Benefits of 3D printing for product designer:

These application are known to offer a considerable amount of benefits to the product designer,

Enhanced Workflow and productivity

Just by having these three elements in-house, there is drastic change in the workflow of a product designer and the focus changes from manufacturing to structural design, stability and longevity as well as overall visual appeal of the product. 3D printing essentially optimizes the designing and testing part of a designer’s work while speeding it up. This allows the designer to focus on the prime matter of concern and increase his productivity, allowing them to foster solution oriented ideas and space for new design processes.

Cost reduction

One of the key factors of implementing 3D printing inhouse for design processes is its cost-effectiveness. When we outsource a prototype, there are various factors involved in the process – multiple iterations, edits, design changes to creating new models – all these can add up to the cost. While having an in-house 3D printer, you can make changes when you want without a long wait period. The initial investment in the technology pays off for itself in the long run.

Also Read: Innovative Product Design Ideas That Impacted The World

Better testing and faster results, more freedom

3D printing saves time and cost, allowing designers more time to design and ideate. In their idea conception to prototype processes, a designer has the freedom to make real-time fixes and build optimized products from a series of testing procedures. With rapid prototyping, a designer can fully understand how the product or part of the product functions under various conditions and thus via this testing process enabling them to make changes before committing to a single idea. Its quick printing post changes allows designers to test as many iterations and ideas as they need.

Reduced Risk

With the opportunity for designers to test, identify spaces for improvement/ any manufacturing hassles and make essential changes – designers have reduced the risk of committing to a single idea as well as the risk of large investments in the manufacturing process. Risk of Intellectual property is also minimized when production is done in-house using 3D printers for prototypes.

Read more: What UX/UI and emerging technologies can do for retail?

Real-life perspective

Product designers are known to ideate and build new ideas with their creative sketches, drawing – digital or by hand – however neither of these give them a real-life perspective of the product, its strength, usability or any issues in the consumption. Modern prototypes are visually appealing and functional products that represent a product design pitch, the idea, its usability in full form and thus creates more business opportunities. Efficient design production gives it a more appealing and real-life perspective making it easy for the designer to test, validate and make the final pitch.

Are you looking to become a product designer? At Strate School of Design, you will learn what product designing is all about, what the industry encompasses, and what the expectations from a product designer are. The course covers various aspects of designing advanced and innovative products where you will also learn to design objects and their usages with a sustainable approach.

Want to Become a Designer ?

Strate is a unique design school that nurtures your talents as a designer by offering state-of-the art designing courses in Bangalore.

Join Strate